- Home

- »

- Custom Cosmetic Labels

Custom Cosmetic Labels & Professional Printing Solutions

Don’t let peeling or faded labels devalue your brand. Secure your skincare line with oil-resistant, high-tack synthetic labels engineered to withstand bathroom humidity and essential oils.

✅ Exact Pantone® Color Consistency

✅ 100% Water & Oil Resistant BOPP

✅ Industrial-Grade Permanent Adhesion

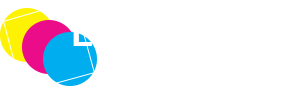

Custom Cosmetic Label Solutions for Diverse Beauty Products

Specialized materials like BOPP and MDO films hedge against oil corrosion and squeeze fatigue, ensuring zero-peel integrity across your entire beauty product portfolio.

Skincare Serum Labels

Engineered with 2.4mil oil-resistant BOPP to prevent edge-lifting and label staining caused by high-concentration essential oils and active serums.

Bath Body Care Labels

High-tack permanent adhesives paired with waterproof lamination ensure 100% adhesion in high-humidity showers, preventing label peeling or unsightly bubbling.

Makeup Color Cosmetics

High-definition 1200 DPI printing for micro-text clarity and specialized finishes like spot UV to ensure high-impact retail shelf differentiation.

Hair Tube Product Labels

Utilizing MDO flexible film technology to prevent tunneling and creasing during repeated tube compression, maintaining label integrity through every squeeze.

Premium Quality Across Every Batch

A glimpse into our high-precision manufacturing—delivering boutique-level aesthetics with industrial-grade reliability for global brands.

Battle Tested Reliability Verification Through Stress

Our engineering standards eliminate production blind spots through rigorous environmental simulation ensuring your specific container types survive every real world challenge.

48H Essential Oil Immersion Test

2.4mil BOPP substrate maintains total bond strength after 48 hours of immersion in high concentration essential oils preventing ink migration or label staining.

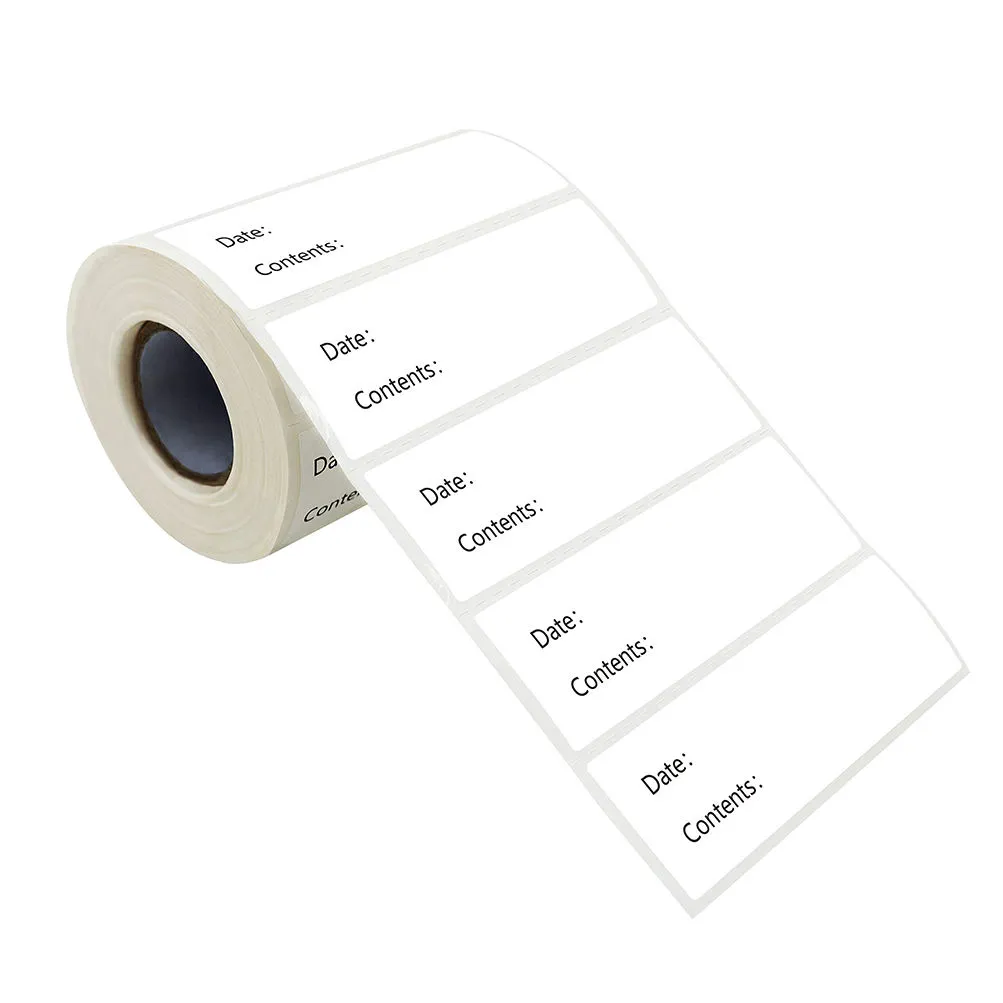

High Humidity Adhesion Cycle Test

Labels endure 95% humidity and fluctuating steam temperatures without bubbling or peeling ensuring permanent adhesion throughout the entire consumer usage cycle in bathroom environments.

Total Reliability from Production to Consumer

Translating engineering specs into business continuity ensuring your product thrives from the high speed production line to the consumers home.

Humidity Proof Brand Permanence

Synthetic BOPP substrates prevent wrinkling and ink degradation during months of bathroom usage protecting premium brand perception and repurchasing rates.

Zero Downtime Compliance Precision

Ultra sharp 1200 DPI printing ensures 4pt text legibility for FDA compliance while optimized unwind directions guarantee seamless automated high speed application.

Strategic Material Selection for Beverage ROI

MDO Flexible vs Standard BOPP

- MDO Conformable Film — Best for squeeze tubes; this highly flexible substrate eliminates label tunneling and creasing during repeated container compression cycles.

- Rigid BOPP Barrier — Best for skincare jars; the dense synthetic structure provides maximum defense against oil migration and chemical product seepage.

Soft Touch Matte vs High Gloss UV

- Tactile Soft Touch — Best for premium positioning; the velvet matte finish creates a luxury sensory grip while resisting fingerprints and oil smudges.

- High Gloss UV — Best for high-vibrance retail; the crystal-clear coating maximizes color depth while providing a hard-shell defense against transit friction.

Engineering Standards and Technical Specifications

High precision material data eliminating production blind spots and ensuring absolute reliability across every unique container type and environmental challenge.

| Primary Substrates | 2.4mil Synthetic BOPP and Flexible MDO Film |

|---|---|

| Adhesive Performance | High-Tack Permanent Acrylic (Water and Oil Resistant) |

| Color Consistency | Precision Pantone Matching (Delta E < 2.0 Standards) |

| Chemical Resistance | Impermeable to Essential Oils, Alcohol, and Humidity |

| Flexibility Index | MDO Technology Optimized for Squeeze-Tube Recovery |

| Application Standards | Custom Unwind Directions (Positions 1-4 for Automation) |

| Regulatory Compliance | FDA 21 CFR 175.105 Compliant Adhesive Systems |

| Printing Resolution | 1200 DPI High-Definition Digital and Flexographic Hybrid |

Verified Field Reliability and Professional Endorsements

Direct feedback from packaging specialists and brand owners who rely on our engineering to secure supply chain integrity and retail perfection.

Have a Question?

FAQ

Common Questions About Custom Beverage Labeling

Why do labels often lift or peel at the edges of small jars?

Will essential oils or creams stain the label surface?

Do these labels wrinkle when the tube is squeezed?

How do you ensure the color matches my brand exactly?

Can I see a sample of my design before the full production run?

Are your labeling materials safe for cosmetic packaging?

Secure Your Production Success Today

Stop risking your brand reputation with guesswork.

Every order includes a comprehensive technical pre-press audit and pre-production sample verification to ensure flawless execution.

12h Expert Response

Free Pre-Press Audit

Direct Factory Pricing

Get Your Factory-Direct Quote

Response within 12 hours. Save up to 30% on bulk orders.

🔒 100% Privacy. No Hidden Costs. Free Sample Options.