- Home

- »

- Custom Nutrition Labels

Custom Nutrition Labels Engineered to Eliminate Recalls and Adhesive Failures

Secure your brand’s integrity with industrial-grade custom nutrition labels designed for 100% FDA compliance and seamless high-speed application, ensuring your premium products remain visually flawless and legally sound from extreme cold storage environments to the most competitive retail shelves.

✅ 100% FDA Supplement Facts Format Verification

✅ Oil, Moisture, and Scuff Resistant Substrates

✅ High-Speed Automatic Labeler Compatibility (Zero-Stretch PET)

Custom Nutrition Labels Built for Industry Performance

Select a labeling solution engineered for your specific product environment. We provide material and adhesive combinations designed to counteract industry stressors like oil exposure and high-speed production.

Dietary Supplement Labels

2.4mil White BOPP combined with aggressive permanent adhesive to prevent flagging on small-diameter pill bottles and jars.

Sports Nutrition Labels

Scuff-resistant matte lamination protecting your brand identity against moisture and friction in high-intensity gym environments.

Liquid Tincture Labels

Oil-resistant coatings ensuring supplement facts remain legible even after repeated exposure to herbal extracts and essential oils.

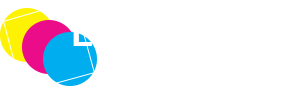

Premium Quality Across Every Batch

A glimpse into our high-precision manufacturing—delivering boutique-level aesthetics with industrial-grade reliability for global brands.

Tested Durability and Compliance Validation

Cryogenic Condensation Challenge

Tested for rapid temperature shifts from cold storage to room humidity. Our permanent acrylic adhesive prevents flagging on high-curvature supplement jars.

FDA Facts Legibility Audit

Extreme scuff and chemical resistance testing with oils and vitamins. Ensures the "Supplement Facts" panel remains 100% legible under harsh handling.

Production Efficiency and Shelf Life Integrity

Engineered for high-speed production. Maximum line uptime. Enduring shelf-life integrity.

High-Speed Bottling Efficiency

Zero-stretch PET liners. High-speed applicator compatible. Eliminates line breaks and production downtime.

Extended Inventory Stability

Anti-yellowing adhesive technology. Fade-resistant UV inks. Maintains premium brand appearance during long-term storage.

Strategic Printing and Surface Protection

Core Production Architecture

- Digital Printing — Best for multi-flavor supplement lines; eliminates plate costs for frequent FDA-mandated ingredient and fact panel updates.

- Flexographic Printing — Best for high-volume retail scaling; delivers the lowest unit cost and rigid color matching for million-unit vitamin runs.

Environmental Surface Defense

- UV Varnish — Best for dry powder containers; provides a cost-effective anti-scuff shield against transit friction and warehouse dust.

- Film Lamination — Best for liquid and oil-based supplements; creates a physical barrier against herbal extracts, leakage, and high-humidity storage.

Technical Nutrition Label Specifications

Engineered for FDA compliance. Built for high-speed application. Guaranteed material stability.

| Primary Substrate | High-Opacity White and Clear BOPP |

|---|---|

| Adhesive Type | High-Shear Permanent Acrylic (Anti-Flagging) |

| Regulatory Standard | 100% FDA CFR Title 21 Compliant |

| Print Resolution | 1200 DPI for Supplement Facts Clarity |

| Chemical Resistance | Resistant to Essential Oils and Alcohol |

| Applicator Liner | PET Zero-Stretch for High-Speed Lines |

| Temperature Range | -40°F to 176°F (Cryogenic to Ambient) |

| Surface Finish | Scuff-Proof Matte or UV Gloss Shield |

Validated Industry Performance

Real-world performance validation from industry leaders who prioritize technical precision and supply chain agility in the competitive wellness market.

Have a Question?

FAQ

Common Questions About Custom Nutrition Labeling.

Why do labels often lift on supplement jars?

Can you ensure my Supplement Facts are FDA compliant?

Will the ink smear if a capsule breaks or oil leaks?

Is digital printing suitable for machine application?

Can I see a physical proof before my full order?

How do you prevent color variance between batches?

Eliminate Labeling Risks Before Printing

Don’t let design errors or wrong materials delay your launch.

Get a free expert review of your artwork and specs to ensure perfect FDA compliance.

12h Expert Response

Free Pre-Press Audit

Direct Factory Pricing

Get Your Factory-Direct Quote

Response within 12 hours. Save up to 30% on bulk orders.

🔒 100% Privacy. No Hidden Costs. Free Sample Options.