- Home

- »

- Custom Juice Bottle Labels

Secure Your Brand Identity With Failure-Proof Custom Juice Labels

Engineered for the brutal realities of the cold chain.

Whether submerged in ice buckets or facing high-pressure condensation, our labels stay locked to your bottles to ensure your premium brand image never peels away before the customer takes a sip.

✅ -20°F Cold-Bond

✅ Delta E < 2.0 Color Accuracy

✅ HPP Compatible Material

Match your beverage application

We eliminate specific packaging failures based on your filling environment and logistics stress.

Cold Pressed Juice Labels

Zero wrinkles from condensation. Our specialized moisture-proof BOPP maintains a flat, premium brand presence even in high-humidity cold storage.

Wellness Shot Labels

Secure wrap for small curves. Ultra-flexible films eliminate edge flagging on 2oz ginger shots and tight-diameter glass containers.

Smoothie and Protein Labels

Armor against shipping friction. Scuff-resistant finishes prevent graphic damage during heavy pallet transit and frequent retail handling of viscous drinks.

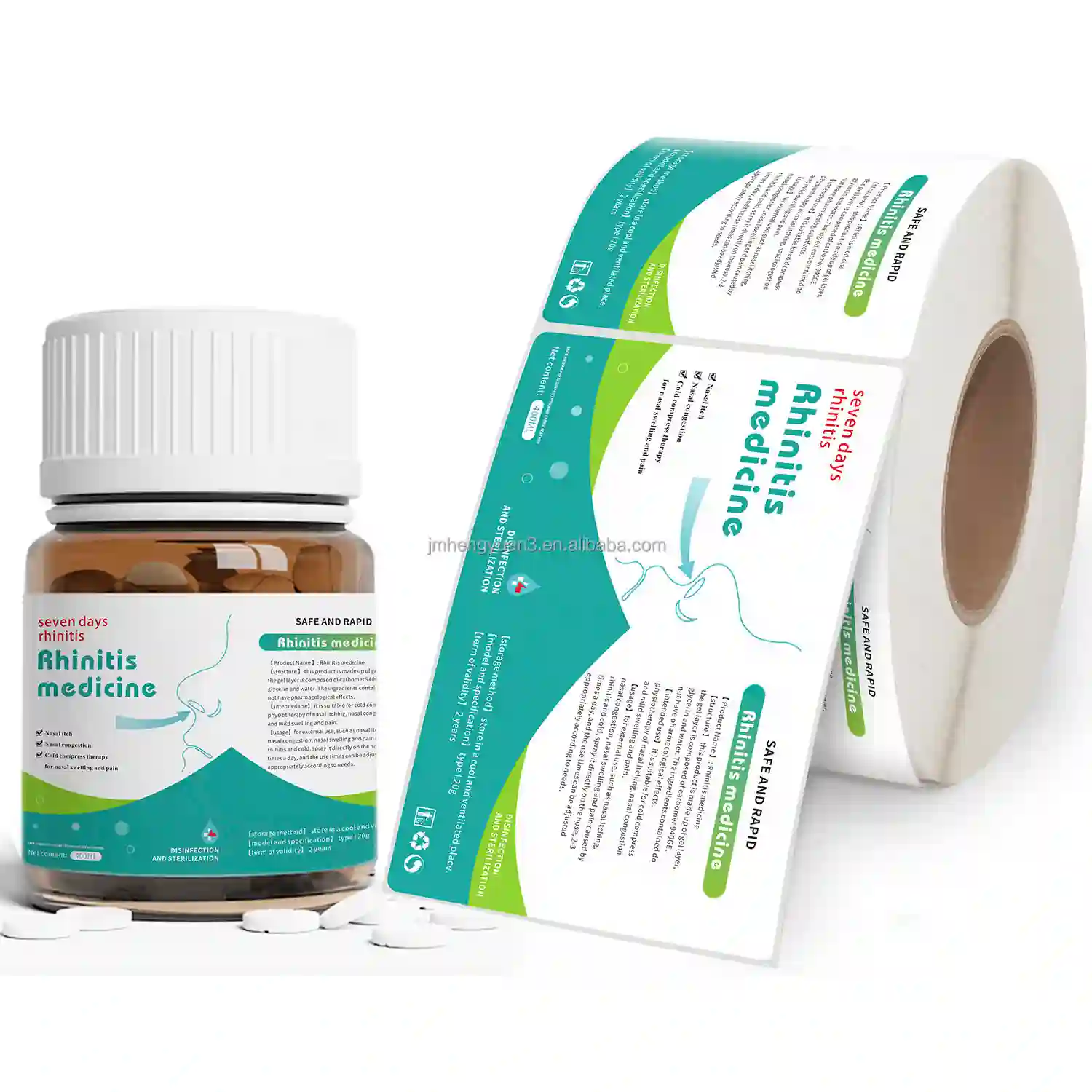

Premium Quality Across Every Batch

A glimpse into our high-precision manufacturing—delivering boutique-level aesthetics with industrial-grade reliability for global brands.

Industrial Precision and Retail Stability

We engineer labels to survive the unique environmental challenges of the cold chain, ensuring your brand’s prestige remains uncompromised from the high-humidity refrigerator to the premium retail shelf.

Waterproof Cold Chain

Waterproof BOPP materials that won't wrinkle, bubble, or mold in 100% humidity cold storage environments.

Transit Scuff Armor

Scuff-resistant UV coatings designed to survive bottle-to-bottle friction during long-distance pallet shipping.

FDA Safety Compliance

Low-migration inks and food-grade adhesives ensure your packaging remains 100% compliant with safety regulations.

High Speed Stability

PET-reinforced liners engineered to prevent snapping on 400+ RPM automated bottling lines for zero-downtime production.

Scale Your Juice Production

Match your bottling volume to the right printing technology to stop overpaying for seasonal flavor tests or risking downtime on high speed industrial lines.

1. Agile paths for seasonal blends

Best for: Small batch cold pressed start-ups and weekly subscription boxes.

The Edge: Eliminate plate costs for every individual fruit recipe. This allows you to test new seasonal flavors with zero dead-stock inventory while maintaining premium waterproof textures at low volumes.

2. Industrial paths for retail volume

Best for: Regional supermarket distribution and high speed automated bottling.

The Edge: Secure the lowest per-unit price for mass production runs. Our toughened liners are engineered to withstand 400+ RPM application speeds without snapping, ensuring your filling schedule stays on track.

Your Reliable Partner

We act as your quality insurance team to ensure your brand never fails on the shelf.

Technical Performance Standards

Hardcore engineering data to eliminate production blind spots and ensure seamless integration with industrial bottling lines.

| Material Face Stock | 2.4mil Waterproof BOPP or Wet-strength Estate Paper |

|---|---|

| Adhesive Grade | Permanent Chill-Grade Acrylic |

| Application Temperature | Min. 25°F to 40°F (Designed for cold and damp bottling) |

| Color Management | Precision Digital Control (Target Delta E < 2.0 for batch consistency) |

| Unwind Direction | Positions 1–8 (Universal automatic applicator compatibility) |

| Print Resolution | Ultra-HD 1200 DPI for micro-text and legal compliance |

| Regulatory Standards | FDA food contact and TTB labeling requirement compliant |

| Release Liner | High-Strength PET or Glassine (Zero-breakage at 400+ RPM) |

Proven Client Results

From high-speed bottling lines to frozen retail shelves, here is how we protect our clients’ bottom line.

Have a Question?

FAQ

Clear your production doubts. We provide expert answers on material durability to protect your brand image and margins.

Why do labels bubble or wrinkle in the fridge?

Will labels peel off small ginger shot bottles?

Do these labels survive 48-hour ice-bucket immersion?

Will graphics scratch off during shipping or handling?

Can I test samples on my bottles first?

Is printing multiple flavors too expensive for startups?

Zero Defect Label Performance

End the fear of labels wrinkling in cold storage or snapping on high-speed lines.

Our expert material review ensures your labels match your bottling equipment and survive every moisture-heavy environment.

12h Expert Response

Free Pre-Press Audit

Direct Factory Pricing

Get Your Factory-Direct Quote

Response within 12 hours. Save up to 30% on bulk orders.

🔒 100% Privacy. No Hidden Costs. Free Sample Options.