- Home

- »

- Custom Roll Labels

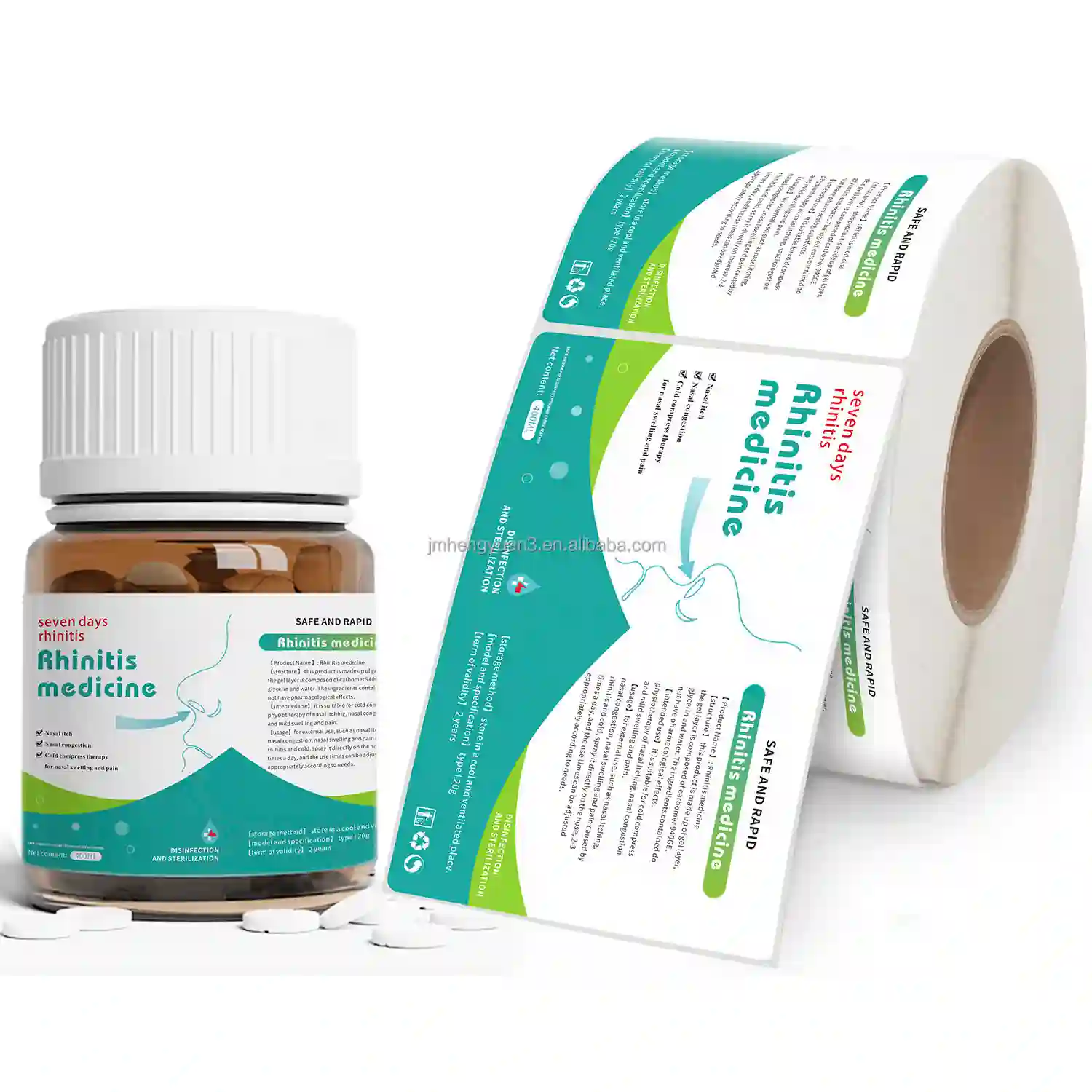

100% Machine-Ready Custom Roll Labels

Stop guessing on technical specs like unwind directions and core sizes.

We deliver factory-direct roll labels engineered specifically for high-speed automatic applicators, ensuring zero-jamming performance and seamless application from the first roll to the last.

✅ Anti-Jamming Substrate Technology

✅ Verified Unwind Positions (1-8)

✅ Industrial-Grade Adhesive (Ice-Bucket Tested)

✅ 2-4 Day Rapid Prototyping

Precision-Engineered Roll Label Solutions

Automated lines demand more than just stickers. We’ve engineered these industrial-grade substrates to ensure your labeling remains consistent, durable, and perfectly compatible with your equipment.

Waterproof BOPP Roll Labels

Ultra-durable 2.4 mil polypropylene construction prevents ink scuffing and edge-lifting in moisture-heavy environments, ideal for beverage and refrigerated food packaging lines.

Textured Estate Paper Rolls

Premium FSC-certified wet-strength paper with tactile textures, engineered to withstand the 24-hour ice bucket test without bubbling or peeling.

Industrial Silver PET Rolls

High-tensile metallic polyester with permanent acrylic adhesive, designed for heat-resistant asset tracking and electronic component labeling in demanding manufacturing sectors.

Flexo vs. Digital: Engineering the Perfect Production Run

Choosing the right printing technology is about more than just ink—it’s about balancing unit cost, color consistency, and machine compatibility.

High-Volume Flexographic Printing

The heavy lifter for bulk orders. This traditional process ensures the lowest per-unit cost and absolute color matching across millions of labels.

Multi-SKU Digital Precision

Perfect for brand owners with multiple product variants. No plate costs mean instant setup and the ability to run 100 designs on one roll.

Premium Quality Across Every Batch

A glimpse into our high-precision manufacturing—delivering boutique-level aesthetics with industrial-grade reliability for global brands.

Engineering Standards & Specifications

Precision is non-negotiable in automated labeling. These engineering specifications ensure a 100% seamless fit for your specific production line requirements.

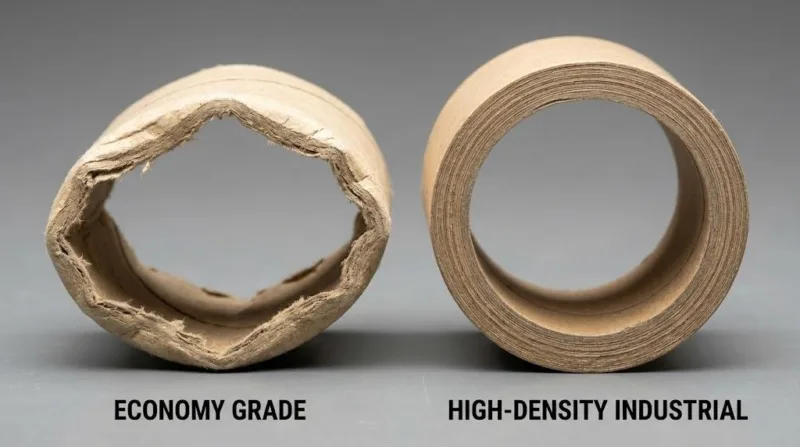

| Core Size Options | Standard 1" (25mm) or 3" (76mm) ID Cardboard Cores |

|---|---|

| Unwind Directions | All Positions 1-8 Available (Top, Bottom, Right, Left Out/In) |

| Max Outer Diameter (OD) | Up to 12" (305mm) to match industrial applicators |

| Label Gap Standard | Precision 0.125" (3mm) or custom spacing for sensors |

| Printing Resolution | 1200 DPI High-Definition for micro-text legibility |

| Material Thickness | 40 - 150 microns substrate options |

| Adhesive Shear Strength | Industrial Grade (>20N/25mm) for high-speed stability |

Zero-Risk Factory Quality Standards

A manufacturing error on your production line is a cost you shouldn’t bear. We’ve built rigid quality protocols to ensure that what you approve as a sample is exactly what arrives in bulk.

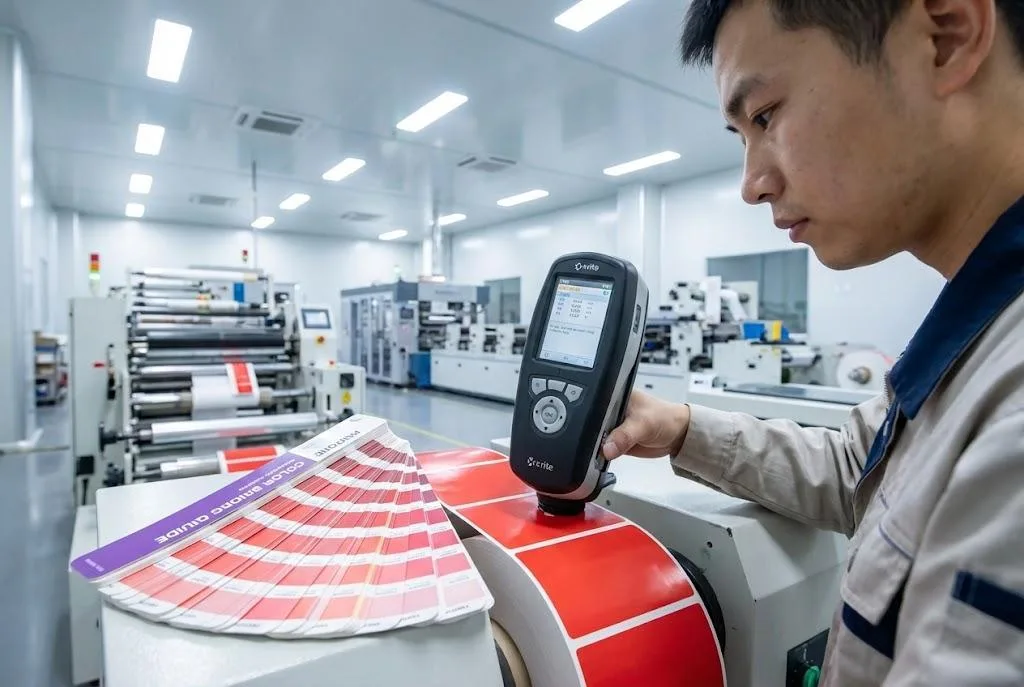

Color Consistency Protocol

Your brand identity shouldn't shift between orders. We utilize X-Rite Pantone color management to ensure re-orders match perfectly every time.

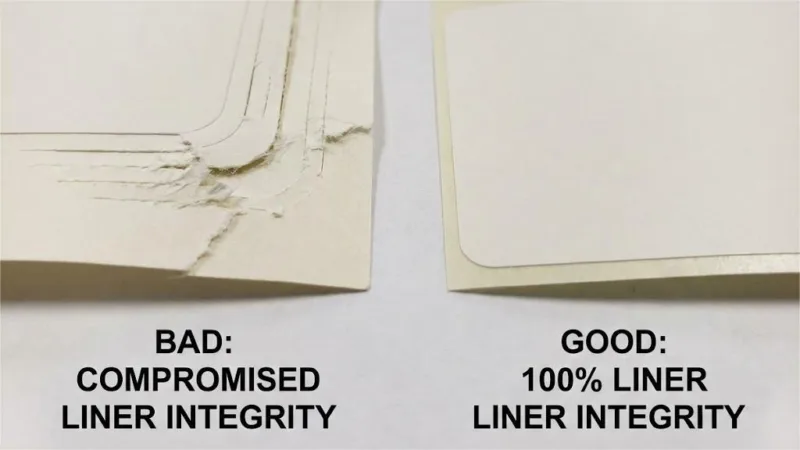

The Anti-Jamming Assurance

Every roll's tension is calibrated to industry standards to prevent web breaks and glue oozing during high-speed application.

Proven Reliability on Every Production Line

See how operations managers and brand owners leverage our 18-year factory expertise to eliminate application errors, ensure anti-jamming performance, and scale their packaging with total confidence.

Have a Question?

FAQ

Quick answers to your roll label specs. For unique project needs, our advisors are ready to assist.

How do I choose the correct unwind direction?

Selection depends on your machine’s feeder orientation (Face Out vs. In) and which label edge leads first. Most industrial equipment follows standard positions 1-8.

Contact us and we can send you a detailed visual chart to help verify the exact match for your manual.

What is the difference between 1" and 3" cores?

3-inch cores are the industrial standard for automatic applicators, while 1-inch cores fit manual or desktop dispensers.

Will these labels withstand refrigeration?

Yes. Our BOPP material is waterproof and maintains a permanent bond even in high-moisture refrigerated environments.

Can I print multiple designs in one bulk order?

Absolutely. Our digital printing allows you to mix multiple SKUs in one run while maintaining bulk pricing discounts.

Can I get a sample kit before a large order?

Yes. We provide custom sample packs so you can test adhesive strength and print quality before committing to production.

How do you protect rolls during shipping?

We use reinforced export packaging and reliable global carriers to ensure your rolls arrive safely without any deformation.

Partner Directly with an 18-Year Manufacturing Expert

Scaling your production requires a partner who understands industrial stakes. Skip the middleman and work directly with our engineering team to ensure 100% machine compatibility.

We protect your budget and your schedule, delivering flawless brand consistency across every roll, from multi-SKU runs to high-volume repeats.

12h Expert Response

Free Pre-Press Audit

Direct Factory Pricing

Get Your Factory-Direct Quote

Response within 12 hours. Save up to 30% on bulk orders.

🔒 100% Privacy. No Hidden Costs. Free Sample Options.