The 60-Minute Emergency Protocol

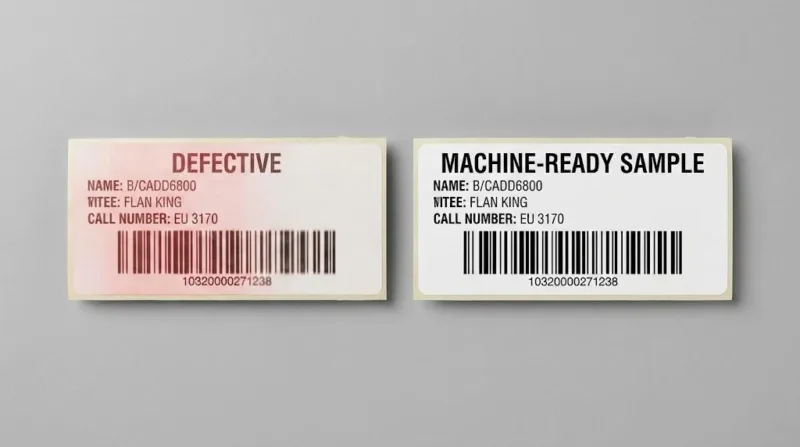

When a shipment fails, the clock is your biggest enemy. You need to move from “discovery” to “documentation” within the first hour. The labels sitting in your warehouse are peeling, off-color, or jamming the sensors, and every minute counts.

- Isolate the Batch: Immediately quarantine the entire shipment. Do not allow a single “maybe” roll to reach the production floor.

- Secure the Evidence: Retain at least 100 sample labels from various parts of the batch (beginning, middle, and end of the rolls).

- Document the “Machine Reality”: If the labels are failing on an automated line, record a 30-second video of the failure (e.g., the liner snapping or the sensor failing to pick up the gap). This is irrefutable proof that the labels are not “machine-compatible.”

The Professional’s Perspective: “Quality is free. It’s not a gift, but it’s free. What costs money are the ‘unquality’ things—all the actions that involve not doing jobs right the first time.”

— Philip Crosby, Author of Quality is Still Free.

Technical Arbitration (Data vs. Opinions)

To win a quality dispute, you must speak the language of the lab. If you tell an overseas factory “the red looks wrong,” they will argue about lighting. If you tell them the Delta E value is 4.5, the argument is over.

| Defect Category | Technical Metric | Acceptance Threshold | Rejection Threshold |

|---|---|---|---|

| Color Accuracy | Delta E ($\Delta E$) | $\Delta E < 2.0$ | $\Delta E > 3.0$ |

| Adhesion Strength | Peel Adhesion (FTM 1) | $12 – 18 N/25mm$ | $< 8 N/25mm$ |

| Scannability | Barcode PCS Value | $> 75\%$ Contrast | $< 40\%$ Scan Error |

| Machine Fit | Unwind Tension | Consistent $15-20$ lbs | Irregular (Snap) |

Why Delta E is Your Best Friend

In professional branding, color consistency is the “silent salesman.” If your labels show a Delta E greater than 3.0, they will look like different products when placed side-by-side on a retail shelf.

As Jules Lejeune, Managing Director of FINAT, notes: “Visual assessment is subjective and leads to disputes. Professional brand owners must transition to instrumental measurement using spectrophotometers to define Delta E as the objective basis for rejection.”

Ready to Secure Your Production Uptime?

Avoid the nightmare of failed inspections with our “Machine-Ready” custom roll labels. We provide full technical audits to ensure 100% compatibility with your automation line.

Calculating the “True” Cost of Failure

Most buyers only look at the invoice price of the labels. This is a fatal mistake. When an imported label batch fails inspection, the real cost is the “Risk Leverage” on your production line.

Understanding the Total Failure Cost (TFC) is essential for recognizing how quality issues directly affect profitability.

The Total Failure Cost (TFC) Formula

Stop asking for just the label cost back. Present your supplier with this calculation to show the gravity of the situation:

- $C_{labels}$: The actual price paid for the batch. This is why a Label Printing Cost Analysis 2026 is vital to see beyond the unit price.

- $T_{down}$: The hours your automated line sits idle.

- $R_{production}$: Your production revenue per hour (typically $1,000 – $10,000/hr).

By showing the factory that their $5,000 shipment is causing $50,000 in losses, you create the urgency needed for them to trigger an emergency re-print.

The Factory-Direct Advantage in a Crisis

This is where the “Direct Source” model beats the “Middleman” model every single time. When a batch fails, a middleman has to negotiate with a third-party factory, who then has to check their schedule.

You are essentially waiting on a game of “telephone” while your line is down. A direct manufacturer can initiate a 48-hour emergency protocol to keep your brand on the shelves.

Response Speed Comparison

- The Middleman (Broker):

- Communication: Relays messages across time zones.

- Decision Power: Zero. Must ask the factory for permission to refund/reprint.

- Resolution Time: 5–10 business days.

- The Direct Factory (Manufacturer):

- Communication: Direct access to the production manager and technical logs.

- Decision Power: Full. Can “cut the line” to prioritize your emergency order.

- Resolution Time: 12–24 hours for a technical plan; 48 hours for a re-print.

Case Study: The “Invisible” Liner Trap

Real Industry Experience:

A few years ago, a brand imported 200,000 roll labels that looked flawless. The color was a perfect match, and the text was sharp. But on the high-speed labeling machine (300 bpm), the liner kept snapping. The supplier (a trading company) blamed the client’s machine tension.

The Factory Owner’s “Lethal” Insight:

We were brought in to consult and didn’t look at the ink—we measured the Release Force Stability. We found the silicone coating on the liner was inconsistent, causing the release force to fluctuate by 40%. The “standard” advice on Google would have had the client wasting weeks adjusting their machine. Our data proved the material was defective at the molecular level, forcing the supplier to admit fault immediately.

The Lesson: If your factory doesn’t provide a Release Force Stability Report for high-speed orders, you are gambling with your production uptime.

Prevention (The Pre-Press Audit)

The best quality dispute is the one that never happens. Professional brands move their “defense” to the beginning of the relationship by implementing a 4-step “Machine-Ready” protocol.

Your Pre-Production Checklist

Before you send the “Go” signal on a 100,000-unit order, ensure your factory has conducted a Pre-Press Audit covering these three pillars:

- Substrate-Environment Match: Will the label be applied to an oily surface? Will it be stored in a -20°C freezer?

- Sensor Compatibility: If you use clear labels, is there a black timing mark on the liner for your machine’s sensor? This is often confirmed through a Remote Audit Checklist before production.

- Unwind Direction: Is the roll wound “labels out” or “labels in”? (Getting this wrong renders the batch useless for automation).

Conclusion: Turning a Crisis into a Partnership

If your imported label batch fails inspection, don’t just look for an exit; look for a partner who is brave enough to talk about the “What Ifs.”

For major defects like scannability issues or adhesive failure, an ANSI/ASQ Z1.4 (AQL) sampling plan provides a structured framework for data-driven decisions.

At the end of the day, you aren’t buying paper and glue. You are buying Production Certainty. By using hard data like Delta E values and Peel Adhesion metrics, you hold your supply chain to a higher standard and ensure that your brand remains on the shelf, where it belongs.

Ready to Ensure Your Production Certainty?

Don’t let a quality dispute stall your brand. Partner with a factory that speaks the language of engineering and guarantees machine compatibility.