Stop letting label-related failures destroy your factory’s efficiency and bottom line. In this guide, I’ll show you the exact technical blueprints for machine-ready label manufacturing that top-tier global brands use to maintain zero-downtime production.

Machine-ready label manufacturing is a specialized production standard that optimizes label physical attributes—including micron-level die-cut precision and consistent release force—to match high-speed applicator requirements, effectively eliminating production line stoppages and maximizing OEE.

Want to see the specific 55% die-cut rule and the ROI formulas that save brands thousands of dollars per minute? Let’s dive into the details.

The Financial Impact of Production Downtime

As we navigate through 2026, the speed of your production line is likely faster than ever. However, speed without stability is a liability. Recent industry data shows that the average downtime cost for an automated production line has climbed to $4,300 per minute.

If you are running a high-volume FMCG (Fast-Moving Consumer Goods) line, a 15-minute stoppage caused by a label liner break does not just delay your schedule—it evaporates $64,500 in direct revenue, wasted materials, and idle labor.

When you sit down to review your annual procurement budget, it is tempting to focus on reducing the unit price of your labels. But does a 5% saving on paper matter if it ruins your OEE (Overall Equipment Effectiveness)?

You should consider the advice of Linnea Keen, President of the TLMI (Tag and Label Manufacturers Institute), who notes that brand owners must look beyond the unit price because the “Total Cost of Ownership” is heavily influenced by how seamlessly a roll performs on the machine. A few “cheap” rolls can quickly negate an entire year’s worth of savings.

Defining Machine-Ready Standards

So, what does it actually mean to be “Machine-Ready”? To us, it is not just a marketing slogan; it is a technical promise. It means the labels you receive are engineered to be a functional component of your hardware, not just a sticker.

We focus on the physical synchronization between the label substrate, the precision of the die-cut, and the specific mechanics of your labeling applicator. This is why we recommend reviewing our Domestic vs. Overseas Label Printing guide to understand the logistical impact of these technical choices.

When your labels are truly machine-ready, they handle the friction, tension, and speed of your 2026-standard equipment without hesitation. Our goal is to move your supply chain away from “commodity printing” and toward “precision engineering.” By focusing on these technical details, you can ensure that your production targets are met and your professional reputation remains secure.

Precision Engineering

To achieve a truly seamless production flow, you must look at your labels through a microscope. In the world of Custom Roll Labels, the difference between a record-breaking shift and a total disaster often comes down to just a few microns.

The 55% Rule for Die-Cut Precision

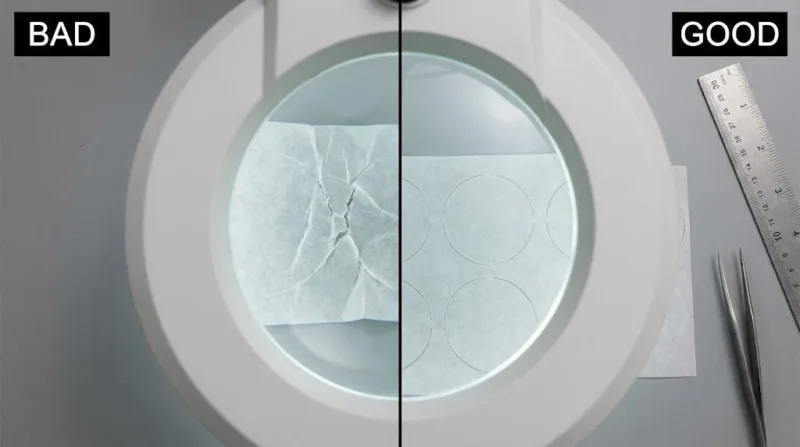

One of the most common, yet invisible, reasons for liner breaks on your high-speed line is “over-cutting.” Most standard suppliers focus on making the label easy to peel, but they often ignore the structural integrity of the backing paper.

If a die-cut blade penetrates more than 60% of the liner’s thickness, you have essentially created a perforated tear-line. Through our years of factory experience, we have found that if the cut reaches 70% depth, the liner’s tensile strength drops by a staggering 80%.

We adhere to the “55% Rule”—ensuring the blade only enters between 50% to 60% of the liner to prevent high-speed breaks. By maintaining a tolerance of ±3μm, we provide the physical insurance your automation needs to stay upright.

Managing the Release Force Window

Even with a perfect die-cut, your labels can still fail if the “Release Force”—the amount of pull required to separate the label from the backing—is inconsistent. For machines running at 300 to 500 PPM, there is a very narrow “Goldilocks” window.

Sandro Kahl, Business Unit Manager at Krones AG, emphasizes that for labeling machines to run at these extreme speeds, the consistency of the release force is non-negotiable. Our technical standard requires this force to stay strictly between 15g and 25g per 25mm. If it fluctuates by even 5g, your machine’s tension compensation system may fail, leading to wrinkles, flagging, or missed applications.

Controlling Surface Static

Static electricity is the silent enemy of automation. In a fast-paced 2026 production environment, labels flying through a machine can generate significant friction. If the surface static on your rolls exceeds 2kV, the labels will begin to “cling” to the metal peel plate instead of dispensing onto your product.

This causes the machine to jam or skip bottles entirely. We use specialized anti-static protocols during the converting process to ensure every roll arrives at your facility ready to run at full velocity without sticking.

Ready to Optimize Your High-Speed Line?

Ensure your labels are 100% compatible with your automated applicators. Get a free pre-press audit and see how precision engineering can save you 30%.

AI-Driven Inspection for Zero-Defect Delivery

In a world where your production line runs at hundreds of units per minute, traditional quality control is no longer enough. Many suppliers still rely on “AQL” (Acceptable Quality Level), which is essentially a fancy term for statistical sampling. But if you are managing a high-stakes pharmaceutical or beverage line, a 1.5% defect rate is not a statistic—it is a disaster waiting to happen.

I once worked with a procurement manager for a German industrial lubricant brand who was losing sleep over a “phantom” sensor error. Every 15 minutes, their high-speed labeling head would trigger a fault, requiring a manual wipe-down.

We discovered the culprit was “micro-oozing”—a tiny amount of adhesive, less than 0.05mm, seeping from the label edges due to improper rewind tension. It was invisible to the human eye but acted like a magnet for dust, eventually blinding the machine’s sensors.

By 2026, the industry standard has shifted to 100% AI Visual Inspection to eliminate micro-defects at line speed. At our facility, we use high-frequency cameras that scan every square millimeter of your labels at speeds of 100 meters per minute. This system catches defects as small as 0.1mm, ensuring a leak rate of less than 0.01% (100ppm).

Syncing with Global Production Lines

One of the biggest anxieties you might face when sourcing from a China-based factory is compatibility. You might wonder, “Will these labels actually work on my Krones or Sidel equipment back home?” It is a valid concern.

Technical specifications on a PDF do not always translate to a smooth run on the factory floor. To solve this, we utilize a “Digital Twin” protocol. We don’t just print your design; we simulate your environment. For more on how to vet overseas suppliers, check our Remote Audit Checklist.

By maintaining a database of technical parameters for major global labeling heads—like the Herma 500 or Quadrel systems—we can adjust the release force and backing paper friction to match your specific peel-plate angle.

We also operate an Applicator Compatibility Lab. Before your order leaves our floor, we run a “simulated sprint” on equipment calibrated to your machine’s settings. This eliminates the “trust black box” of international sourcing.

| Technical Metric | Industry Standard | “Machine-Ready” Goal |

|---|---|---|

| Die-Cut Depth | 70%+ Penetration | 55% (±3μm Tolerance) |

| Release Force | Variable/Untested | 15g – 25g Consistency |

| Surface Static | Uncontrolled | Below 2kV Protocol |

The Real Mathematics of Your Labeling Budget

How do you justify a slightly higher label price to a procurement department that is laser-focused on “unit cost”? You show them the math. To make an informed decision in 2026, you need to look at the Total Cost of Ownership (TCO) rather than just the price on the invoice.

We recommend using this simple formula to evaluate any new supplier:

Total Cost of Labeling = (PL × Q) + (TD × CH) + (WL × PP)

In this equation, PL is your label price and Q is quantity. However, the real “budget killers” are TD (Total annual downtime hours) and CH (Hourly downtime cost). When you plug in the numbers, a supplier who is 10% cheaper but causes just two extra hours of downtime per year is actually the most expensive choice you can make. This is a common realization found in our Label Printing Cost Analysis.

Three Questions for Your Next Supplier Audit

Before you sign your next annual contract, you should put your potential partner to the test. Don’t settle for vague promises. Instead, ask these three hard questions:

- “Can you provide a micron-level report of your die-cut depth consistency across a 50,000-label run?” (If they don’t mention the 50-60% liner rule, they aren’t ready for high speed).

- “What is your protocol for detecting micro-oozing and adhesive bleeding before the rolls are wound?” (Look for 100% AI visual inspection).

- “Do you have a compatibility lab to test my specific machine’s peel-plate angle and sensor type?” (This ensures they are engineering, not just printing).

Securing Your Production Future

Choosing the right partner is about more than just buying stickers; it is about protecting your production targets and your sanity. By focusing on the invisible technical markers—like micron-level tolerances and AI-verified defect rates—you transform your labels into a competitive advantage.

At Label Printing China, we have spent 18 years mastering these details so that you don’t have to worry about them. Our commitment to Machine-Ready Label Manufacturing ensures that when you hit the “start” button, you focus on output, not downtime.