Approving a 10,000+ label run is a high-stakes decision that can make or break your production timeline. This industrial-grade protocol gives you the exact SOP needed to prevent costly recalls and machine downtime before you hit print.

To safely sign off on a label run, you must verify three technical pillars: Color Consistency (using Delta-E < 2.0 metrics), Adhesive Stability (via 24-hour environmental stress tests), and Mechanical Compatibility (matching unwind direction and roll OD to your applicator). Moving beyond visual proofing to technical validation prevents 90% of production-line failures.

But the “visual check” is where most managers fail. Read on to discover the “1-10-100” cost rule and the technical audit that prevents $50,000 recalls before they start.

Why “Good Enough” is Never Enough

Before we dive into the technical steps, let’s look at the cold, hard numbers. In quality management, we follow the 1-10-100 Rule. This visualizes how the cost of an error escalates the further it travels down the supply chain.

| Phase of Detection | Action Required | Cost Multiplier | Estimated Loss (per 10k units) |

|---|---|---|---|

| Pre-Sign Off (Digital/Press Proof) | Minor design/text edit | 1x | $50 – $100 (Labor only) |

| Post-Production (At Factory) | Complete re-print & material waste | 10x | $1,000 – $3,000 |

| At the Application Line | Production downtime & labor idle time | 50x | $5,000 – $10,000 |

| On the Retail Shelf / Recall | Logistics, fines, and brand damage | 100x+ | $50,000 – $100,000+ |

The Lesson: Spending an extra 30 minutes on a technical audit during the Essential Steps Before Signing Off Label Run phase is the highest ROI activity you will perform all year.

Moving From “Visual Approval” to “Digital Color Standards”

Most supply chain managers fall into the trap of approving a digital proof on a backlit computer screen. This is a fundamental error. Your screen emits RGB light; your labels are printed with CMYK or Pantone inks on physical substrates. They will never look identical.

The Delta-E Mandate

To achieve true consistency, you must speak the language of physics, not “feelings.” In 2026, professional sign-offs require Delta-E metrics. Delta-E measures the distance between two colors in a mathematical space.

- ΔE < 1.0: Invisible to the human eye.

- 1.0 < ΔE < 2.0: Standard for high-end B2B labels.

- ΔE > 3.0: Visible color drift that can lead to “counterfeit” suspicions on the shelf.

Expert Insight: Ron Ellis (G7 Expert & Idealliance Chair)

“Brands often sign off on a single sheet but fail to specify the tolerance. For any run over 10,000 units, you must define the Delta-E limit in your sign-off agreement. Without a quantified tolerance, you have no legal or technical standing to reject a shipment that ‘looks slightly off’ under retail lighting.”

Your Actionable Checklist:

- Request L*a*b* coordinates: Ensure your core brand colors are defined by data, not just a swatch.

- Physical Substrate Proofs: Never sign off until you see the ink on the actual material (PP, PET, or recycled paper). Different materials have different “absorption” rates that drastically change color.

- Digital Press Check: For large runs, use a spectrophotometer to verify the first 50 labels (The Golden Sample) match your master file.

The “Micro-Climate” Protocol (Environmental Stress Testing)

A label is a high-performance engine. It must survive the journey from a hot shipping container in Texas to a sub-zero freezer in New York. If you only test the label in your office, you are ignoring its lifecycle.

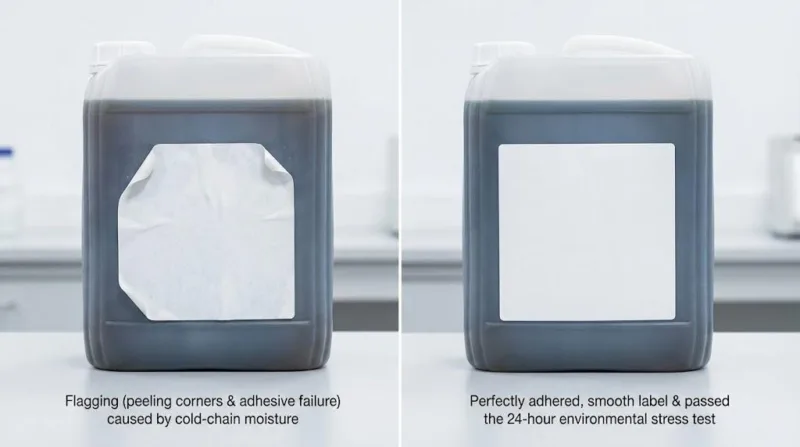

The “Cold-Chain Escape”

I recently worked with a client who approved 30,000 labels for a premium frozen food line. They checked the spelling and the colors perfectly. However, 24 hours after the labels hit the -18°C cold storage, they began to “flag” (peel at the edges).

The client had tested the Initial Tack at room temperature but ignored the Service Temperature and the moisture condensation that occurs during the freezing process.

Turn the Tide

You must demand an Adhesive Failure Stress Test. This involves placing labeled containers in a climate-controlled chamber to simulate:

- Thermal Shock: Rapid moves from 25°C to -20°C.

- Shear Strength: How well the glue holds up under the constant vibration of truck transport.

- Chemical Resistance: If you are in the beauty or medical industry, will the ink run if it touches isopropyl alcohol or essential oils?

Ready to Secure Your 10,000+ Label Run?

Stop risking production line failures. Get factory-direct labels that are 100% machine-ready and tested for your specific environment.

Choose Your Adhesive Wisely

- Permanent Acrylic: Good for general use.

- Rubber-Based: High initial tack, but poor UV resistance.

- Cryogenic Adhesives: Mandatory for pharmaceutical or deep-freeze food applications.

The Mechanical Audit (Application Line Compatibility)

This is where the most expensive mistakes happen. You can have the most beautiful label in the world, but if it doesn’t fit your Automatic Label Applicator, it is effectively trash.

The Unwind Direction Disaster

There are 8 standard Unwind Directions (the orientation of the label on the roll). If your machine expects Position #4 (Right Out) and you sign off on Position #1 (Top Out), the labels will be applied upside down. Re-winding 10,000 labels is not only a labor cost; it often stretches the Liner (the backing paper), causing the labels to “pre-dispense” and jam the machine.

The “Applicator Sync” Audit

- Roll Outer Diameter (OD): Use the formula $D = \sqrt{\frac{L \cdot t}{0.0625} + d^2}$ to ensure the roll isn’t too heavy for your machine’s motor.

- Liner Thickness: Ensure a tolerance of ±5%. If the liner is too thin, it will snap under the tension of a high-speed bottling line.

- Barcode Grade Verification: Don’t just scan it with your phone. According to barcode verification standards, labels must meet ISO/IEC 15416 standards. Aim for a Grade B (3.0) or higher. Anything lower increases the risk of retailer chargebacks by 40%.

I always tell my clients: Don’t just sign the design. Send me the technical manual for your labeling machine. We will match the roll tension and core size (typically 3″) to your exact hardware before the first drop of ink hits the paper.

2026 Compliance and The “Digital Twin”

As we move toward 2026, your sign-off is no longer just about quality; it’s about legal survival. Governments are introducing strict EPR (Producer Responsibility Extension) laws, specifically in markets like California SB 54.

Your 10,000+ label run must now account for its “end-of-life.”

- RecyClass Standards: Does your adhesive contaminate the recycling stream?

- Carbon Score: Is your factory using low-VOC inks?

- Digital Product Passports (DPP): Many 2026 labels will require dynamic QR codes that provide transparency to consumers.

In 2026, humans should not be checking for typos on 10,000 labels. We now use AI Vision Systems that perform “Pixel-to-Pixel” comparisons. This software overlays your original PDF onto the printed result and flags even a 0.1mm deviation. This is the only way to ensure 100% accuracy in highly regulated industries like medicine or chemical manufacturing.

The “Golden Sample” Final Defense

The most successful supply chain managers never consider the “Sign-Off” as the end of the process. They treat it as the beginning of the First Article Protocol.

- Authorize the Press Start: Sign the proof based on the technical metrics (Delta-E, Unwind Position, Adhesive Grade).

- The 50-Unit Pull: Request that the factory pauses after the first 50 units. These are your “Golden Samples.”

- Physical Verification: Have those 50 units overnighted to your facility or verified via a high-resolution video link using AI-visual tools.

Final Thought: In the B2B world, certainty is the ultimate currency. By following these Essential Steps Before Signing Off Label Run, you are not just buying labels; you are buying insurance for your production line, your brand reputation, and your peace of mind, especially when backed by professional label quality dispute management.

Ready to Start Your Printing Partnership?

You’ve created the vision. Now let our experts handle the 10,000+ label run with the quality and “machine-ready” precision your project deserves.