Raw material prices are swinging wildly, and your label budget is caught in the crossfire. It feels like you’re powerless against market volatility, but there is a proven way to regain control and stop overpaying.

To effectively protect your label budget amidst raw material fluctuations, companies should adopt index-based pricing tied to market benchmarks, implement gauge reduction to lower substrate volume, and maintain physical inventory reserves. These strategies transition procurement from reactive buying to proactive risk management.

But those high-level tactics are just the beginning. Stick with me to see the exact formulas and “invisible” material engineering hacks we use to save CPG brands thousands every year.

Moving to a Formulaic Pricing Model

The biggest mistake you can make in 2026 is treating your label price as a “black box.” When you don’t know the cost breakdown, you are at the mercy of the market. Instead, you should implement an Index-Based Pricing Model.

Think of this model not as “complex math,” but as a fairness shield. It ensures you only pay more when raw materials actually rise, and—more importantly—you pay less when they fall. This approach shifts the conversation from a vague “total price” to a transparent formula:

The “Transparency” Formula Explained:

- ✅ Base Price: Your starting price when we sign the contract.

- ✅ Material Weight: The specific % of the label cost that is raw material (usually 45-55%).

- ✅ Market Change: The actual fluctuation tracked by the Producer Price Index (PPI).

The Formula in Practice: A Real-World Scenario

Let’s strip away the variables and look at a concrete example. Imagine your current label cost is $10.00 per unit, and 50% of that cost is paper ($5.00). If the global paper index suddenly jumps by 10%:

- The “Black Box” Vendor: Might try to raise your total price by 10%, charging you $11.00.

- The Index-Based Model: Only the 50% material portion increases. Your new price is $10.50.

By using this model, you instantly save 5% compared to traditional “gut-feeling” price hikes. You lock in the “conversion cost” (our labor and profit) while ensuring your material costs move in perfect sync with the global market—never a penny more.

For procurement professionals, understanding the mechanics of a strategic guide on price indexation is the first step toward building a truly resilient budget that withstands global commodity shifts.

Summary: Why Transparency Wins the Budget War

| Pricing Feature | Fixed-Price Contract | Index-Based Pricing |

|---|---|---|

| Risk Premium | High (Suppliers hide 5-8% extra to cover potential inflation) | Zero (You pay only for actual market movement) |

| Price Drops | You never see the savings when raw material prices fall | Automatic price reduction when the index falls |

| Relationship | Adversarial (Haggling over every cent during spikes) | Partnership (Focus on joint operational efficiency) |

Koray Köse, Senior Director Analyst at Gartner, emphasizes that “Procurement leaders must move away from adversarial vendor negotiations. Transparency regarding resin and pulp indices is the only way to avoid ‘panic-buying’ premiums.”

Finding “Invisible” Savings

If your finance department is demanding a 10% budget cut while material prices are rising, you cannot win by simply asking for a discount.

You win through Material Engineering by looking at the physical properties of your labels to find hidden waste.

The Power of Gauge Reduction

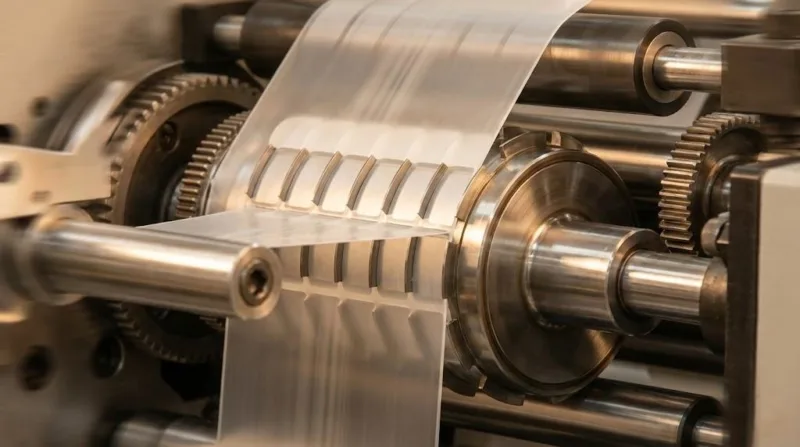

One of the most effective strategies to protect your label budget amidst raw material fluctuations is reducing the thickness of your materials. In our factory, we have helped clients transition from a standard 2.4 mil face stock to a 2.0 mil film.

These adjustments are similar to the process improvements highlighted in Six Sigma DMAIC case studies in printing, which show how precision tweaks lead to massive waste reduction.

- The Result: An immediate 8% to 12% reduction in raw material spend.

- The Bonus: Because the material is thinner, you get 15% to 20% more labels per roll (switching from a 40# to a 30# liner).

- The Impact: This translates to 15% fewer roll changes on your production line and 15% lower shipping costs.

Ready to Reduce Your Total Label Spend by 30%?

Stop the guesswork. Let our experts handle a free pre-press audit to identify your gauge reduction and SKU consolidation opportunities today.

SKU Consolidation Audit

Are you buying 50 different label sizes for 50 different products? You are likely paying a “small batch” premium on 80% of your inventory.

By auditing your packaging and standardizing to 5 or 10 universal sizes—using variable digital printing for specific product info—you can trigger volume discounts that reduce unit costs by up to 22%. Understanding the total cost of ownership in label printing is vital to unlocking these hidden efficiencies.

The 2026 EPR Compliance Roadmap

The cost of your label is no longer just “material + labor.” In 2026, you must factor in the Extended Producer Responsibility (EPR) surcharges.

In states like California, using non-compliant, non-recyclable labels can result in “plastic taxes” ranging from $0.01 to $0.05 per unit. Detailed legal insights on state EPR laws warn that brands must audit their materials now to avoid these regulatory surcharges.

Balancing Sustainability and Budget

Many procurement managers fear that “eco-friendly” means “expensive.” However, if you wait until the last minute to switch, you will face a “compliance premium” as every brand rushes for the same certified recycled materials.

- Proactive Strategy: Adopt materials with 30% Post-Consumer Recycled (PCR) content now.

- The ROI: While the material may cost 5% more upfront, you avoid the $0.05 per unit fine, leading to a massive net saving over the fiscal year.

Paul Nowak, Executive Director at GreenBlue, warns that “The cost of non-compliant packaging will soon surpass the cost of premium eco-friendly materials.”

The Inventory Hedge

In a volatile market, the most expensive label is the one you don’t have. A production line stoppage costs far more than a 5% material spike. To truly protect your budget, you must secure your Physical Inventory through strategic partnerships.

The “Priority Allocation” Strategy

Don’t just sign a contract; verify the warehouse. A strategic partner should offer a Vendor Managed Inventory (VMI) agreement.

This isn’t just “stocking labels”; it is the factory pre-purchasing 3 to 6 months of your specific raw materials (pulp and resin) during market dips. To ensure your supplier has the capacity, follow our checklist to vet a China-based label factory before signing long-term deals.

Label Printing China Pro Tip: We advise our clients to include a Cap Assurance Clause. This ensures that even during a global material shortage, your “allocated volume” is physically in our warehouse, locked at the pre-spike price.

The “Quality Swap” Trap

I want to share a story about a premium beverage brand that came to us after a disastrous Q3. They had signed a “fixed-price” deal with a vendor who promised to ignore the 30% market spike in adhesive costs.

Because the vendor couldn’t afford the loss, they performed a “Quality Swap” without telling the client. They switched an 80g face stock for a 70g alternative and used a cheaper, standard adhesive instead of the required cold-chain grade.

- The Result: The labels fell off in the grocery store refrigerators.

- The Cost: The client lost $250,000 in rejected stock—all to “save” $5,000 on the initial quote.

The Lesson: Never accept a “too good to be true” price lock without Material Traceability. Demand to see the Technical Data Sheets (TDS) and Lot Numbers for every shipment. If your supplier won’t show you their raw material invoices, they are likely hiding a quality compromise.

Summary Checklist for 2026 Budget Protection

To ensure your label budget remains resilient against the next raw material fluctuation, ask your current supplier these four questions:

- Transparency: “Can we move to an index-linked pricing model for our 2026 contract?”

- Engineering: “Can we perform a Gauge Reduction test to see if 2.0 mil film works on our lines?”

- Compliance: “What is our specific cost exposure to the new EPR laws for our current SKU list?”

- Resilience: “Do you have 90 days of our specific face stock physically in stock right now?”

Take the Next Step

Budget protection is about data, not just negotiation. If you are unsure where your hidden waste is or how the 2026 regulations will impact your bottom line, we are here to help.

Label Printing China offers a complimentary Label Spec Audit for CPG brands. We will analyze your current material thickness, adhesive grades, and SKU counts to find the “invisible” savings that protect your budget without sacrificing the quality of your brand.